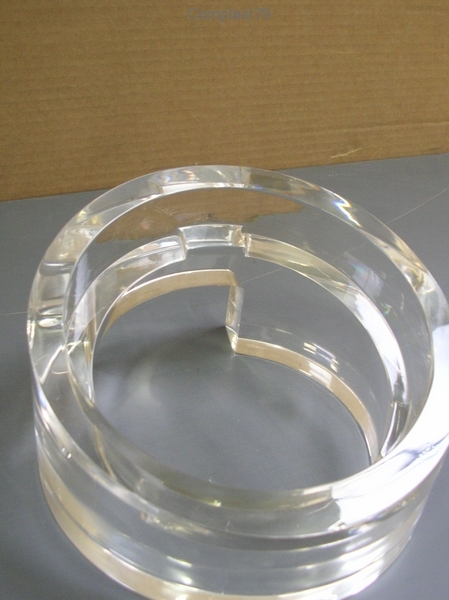

Plexiglass processing

Design and construction of chemical resistant products for industries.

Complast79 carries out industrial processing in Polymethylmethacrylate or PMMA (more commonly called with commercial names such as PLEXIGLASS, PERPEX, LUCITE, VITROFLEX, LIMACRYL, PLEX etc.) and mechanical processing in Polycarbonate or PC (with commercial names such as LEXAN, EXELL, GEPAX, LEXGARD etc.), are materials which, thanks to their characteristics of mechanical resistance, chemical resistance, transparency and availability in a vast range of colors, are now used in various sectors such as industrial plant engineering, construction of roofs and skylights, advertising for the creation of displays trade fair stands, furniture for tables, stairs and various objects, optical, electronic, workplace safety for the creation of accident prevention barriers and industrial machinery protections and in all those situations where it is necessary to create particular resistant and transparent products, but using glass or crystal is not possible or desiderable. Furthermore, these materials are available in sheets, tubes, bars and profiles of various diameters and thicknesses.

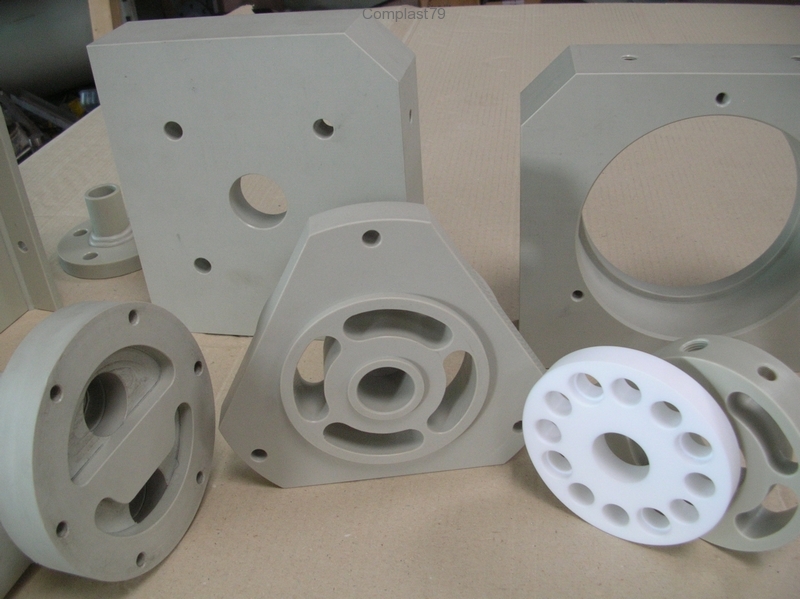

Plastic material processing

Polymethylmethacrylate (PMMA) and Polycarbonate (PC) are two plastic materials commonly used for the production of mechanical parts in various sectors.

Here are some examples of mechanical parts that can be produced with these materials:

Transparent or translucent sheets and panels:

Both PMMA and Polycarbonate are known for their transparency and translucency, making them ideal for the production of sheets, panels or covers used in sectors such as construction (glazing, skylights), the lighting industry (diffusers of light), and the production of displays.

Protective cases and covers:

Both PMMA and Polycarbonate can be molded or machined to create cases, covers and protectors for electronic devices, machines, tools and other equipment.

Components for the automotive industry:

Polycarbonate is often used for the production of headlights, taillights, rearview mirrors, dashboard covers and other automotive components due to its resistance to impacts and UV light.

Decorative elements and design components:

Both materials can be shaped and worked to create decorative elements such as sculptures, art objects and interior and exterior design components.

Materials for the aeronautical and aerospace industry:

Polycarbonate is known for its lightness and strength, and is used to produce aircraft components such as windows and roofing parts.

Components for the lighting industry:

PMMA is often used in the production of diffusers, lenses and other components for lighting fixtures due to its transparency and ease of processing.

Elements for the furniture industry:

Both materials can be used to create furniture, shelves, tables, chairs and other furnishing elements thanks to their ductility and flexible design.

Components for the medical industry:

PMMA and Polycarbonate are used to manufacture medical devices, including protective gear, imaging devices and medical equipment parts.

In general, there are wide possibilities of producing mechanical parts with PMMA and Polycarbonate, depending on the specific properties of the materials, the design requirements and the final applications. Both materials are valued for their light weight, impact resistance, corrosion resistance and shaping ability, making them suitable for a wide range of industrial and commercial applications.

Engine cover in plexiglass

Plexiglass column

Plexiglass products created by COMPLAST 79

data sheet

Abbreviations for names of plastic materials:

PP datasheets:

datasheets: C-PVC, PMMA, ABS:

datasheets: Polisulfone, Acetal, Policarbonato:

PP-PVC-PEHD-PVDF